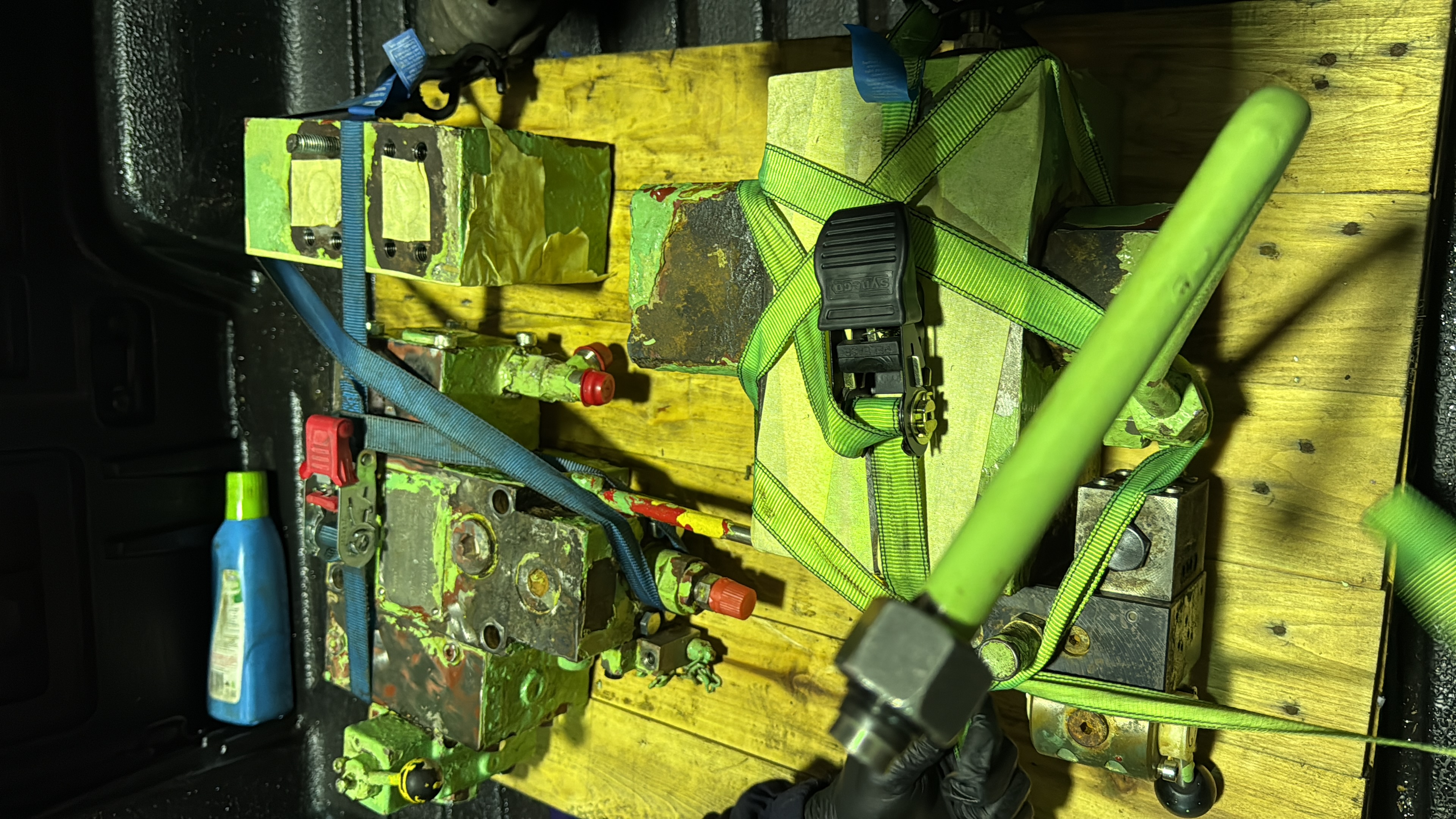

Qualships Completes Critical Hydraulic Repair at Port Botany Port Botany, Australia — 17 May 2025 In a successful display of marine engineering expertise, Qualships Pty Ltd has completed the comprehensive rectification of an inoperative starboard windlass/mooring winch hydraulic system aboard a major container vessel. The intervention took place at Port Botany under instruction from Ship Owner, ensuring minimal downtime and restoring critical anchoring capabilities to the vessel. Upon boarding and conducting initial diagnostics, the Qualships engineering team identified a complete failure in the hydraulic system. Pressure readings taken after the control block and before the hydraulic motor indicated zero pressure—pinpointing a fault within the control block as the root cause. The control block, comprising three sections, was systematically dismantled and off-landed along with associated hydraulic piping. The blocks were cleaned, disassembled, and thoroughly inspected at the shore facility. A major issue was identified in the pilot assembly cartridge valve, where a broken washer and debris had caused internal flow bypass, rendering the windlass inoperative. Key remedial actions included: Renewal of all seals, O-rings, and backup rings. Replacement of all nuts and bolts. Polishing of cartridge valve and slide surfaces. Removal and rethreading of broken studs from Block C. Post-repair, the control blocks underwent bench testing and were reinstated onboard. Final system trials confirmed full restoration of the starboard windlass/mooring winch, now operating to standard. Recommendations: Qualships advises regular inspection of hydraulic components, timely flushing, and filter replacement schedules to avoid similar faults in future. This successful operation reinforces Qualships’ commitment to delivering high-quality marine engineering support with minimal operational disruption. For more information about Qualships services, please contact info@qualships.com or visit www.qualships.com.