Latest News & Updates.

Stay updated with our latest projects, achievements, and industry insights.

Successful Hull Plate and Bracket Repair Completed at Port Hedland Anchorage

Qualships Engineering was engaged to carry out permanent hull repairs on the port side shell plate and associated bracket at frame No. 77. The repair was executed onboard at anchorage under tight time constraints — and delivered in record turnaround time. Job Summary: • Damage Identified: Cracks observed on the shell plate and bracket at L51 longitudinal – Frame 77 (Port Side). • Repairs Carried Out: • Shell Plate Renewal – 915 mm × 815 mm × 18 mm, EH36 grade • Bracket Renewal – 830 mm × 420 mm × 18 mm, EH36 grade • Double-V weld preparation, ceramic backing applied • All welding performed by DNV-approved welders under WPS • Testing & Inspection: • Visual inspection and NDT (MT & Dye Penetrant) completed satisfactorily • Hydrostatic pressure test on No.8 Water Ballast Tank successfully conducted • Class approval granted by CCS upon inspection

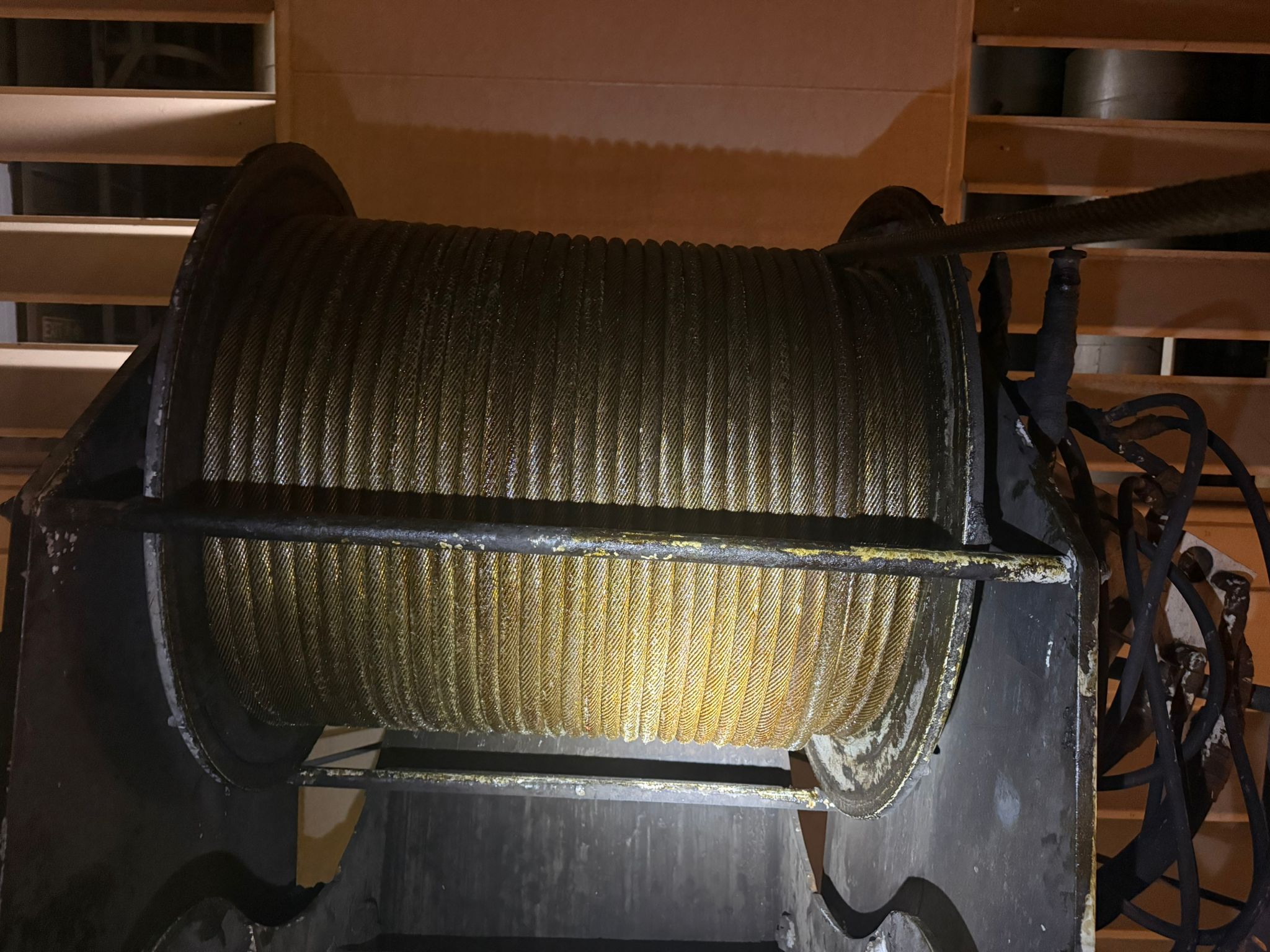

Read More...LIEBHERR Crane – CBW 45(40) Hoisting Wire Replacement Completed Successfully in Brisbane! ⚓

🔧 LIEBHERR Crane – CBW 45(40) Hoisting Wire Replacement Completed Successfully in Brisbane! ⚓ We are proud to announce the successful completion of hoisting wire replacement for the Liebherr Marine Deck Crane, Type CBW 45(40), carried out efficiently alongside berth in Brisbane. 🛠️ Scope of Work Included: Safe removal of the worn hoisting wire Installation of new OEM-specified wire rope Drum re-spooling and tensioning operations Full functional testing post-installation ✅ The job was completed safely, within port time, and in compliance with class and manufacturer guidelines. A big thank you to our on-site team and coordination partners who ensured a smooth and timely execution. 👷♂️⚙️ 📍 Location: Brisbane Port – Alongside Berth 📅 Date: 28/05/2025 🔩 Crane Type: LIEBHERR CBW 45(40)

Read More...ROLLS ROYCE WINDLASS /WINCHES HYDRAULIC TROUBLE RECTIFICATION

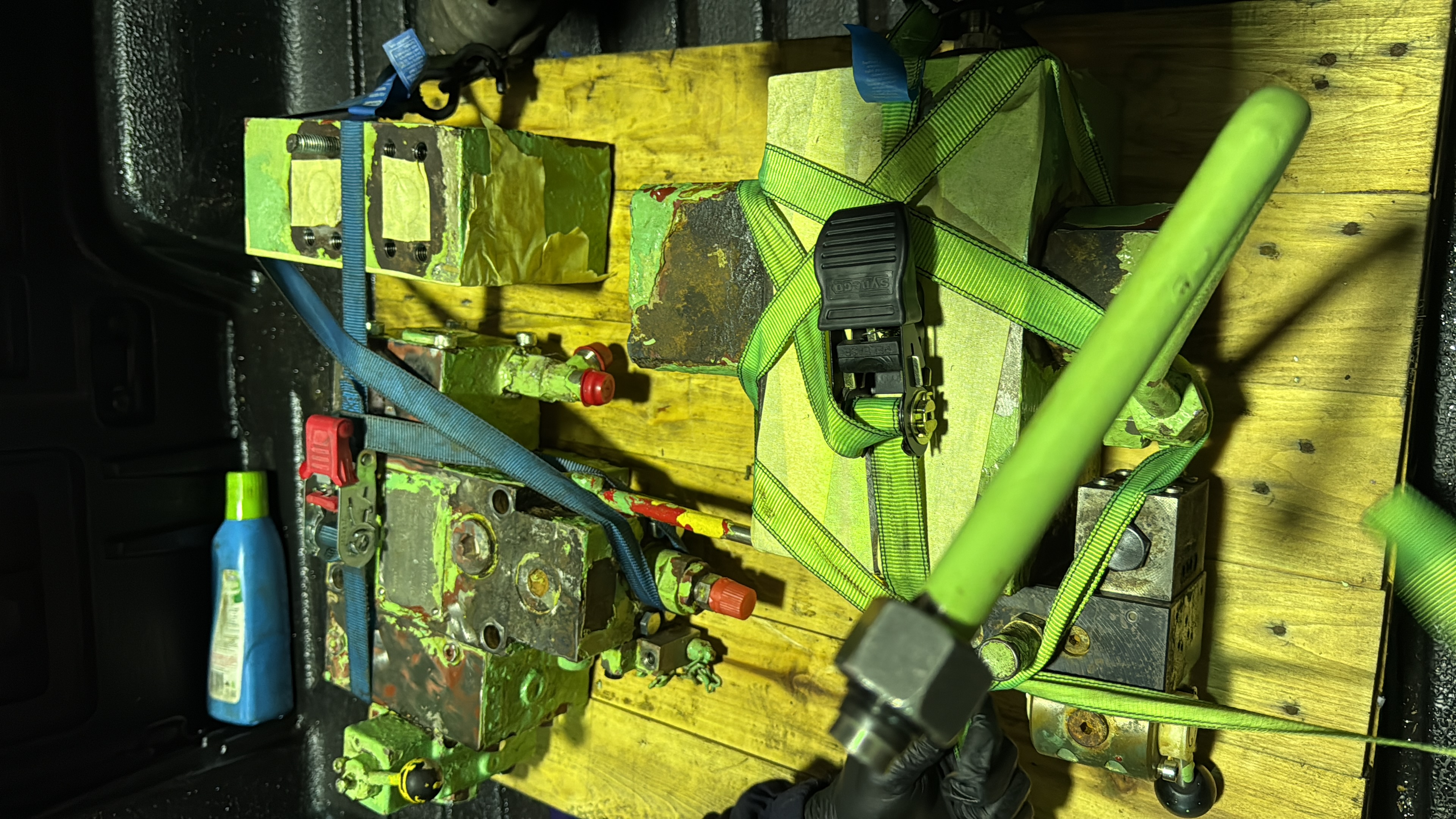

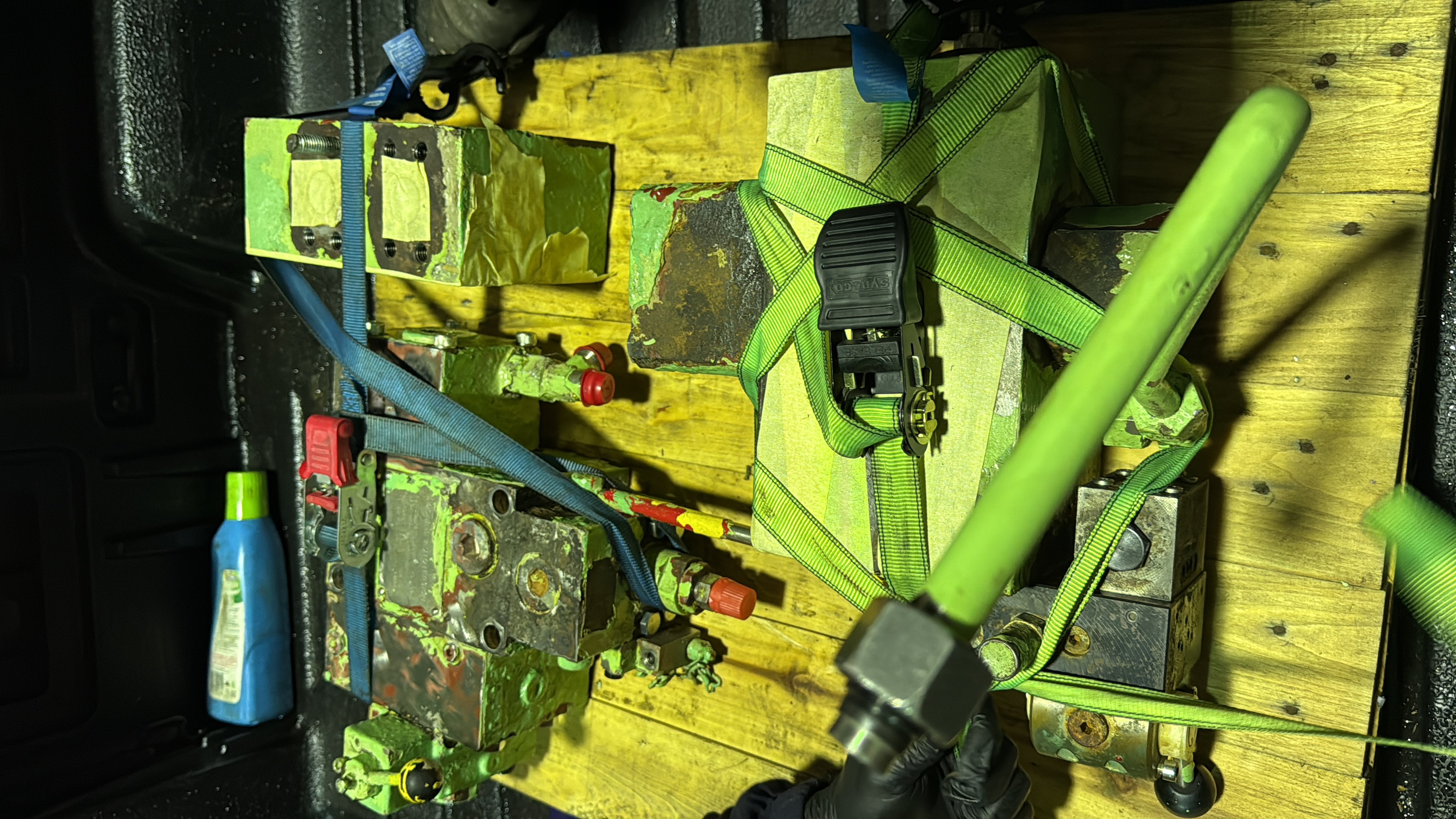

Qualships Completes Critical Hydraulic Repair at Port Botany Port Botany, Australia — 17 May 2025 In a successful display of marine engineering expertise, Qualships Pty Ltd has completed the comprehensive rectification of an inoperative starboard windlass/mooring winch hydraulic system aboard a major container vessel. The intervention took place at Port Botany under instruction from Ship Owner, ensuring minimal downtime and restoring critical anchoring capabilities to the vessel. Upon boarding and conducting initial diagnostics, the Qualships engineering team identified a complete failure in the hydraulic system. Pressure readings taken after the control block and before the hydraulic motor indicated zero pressure—pinpointing a fault within the control block as the root cause. The control block, comprising three sections, was systematically dismantled and off-landed along with associated hydraulic piping. The blocks were cleaned, disassembled, and thoroughly inspected at the shore facility. A major issue was identified in the pilot assembly cartridge valve, where a broken washer and debris had caused internal flow bypass, rendering the windlass inoperative. Key remedial actions included: Renewal of all seals, O-rings, and backup rings. Replacement of all nuts and bolts. Polishing of cartridge valve and slide surfaces. Removal and rethreading of broken studs from Block C. Post-repair, the control blocks underwent bench testing and were reinstated onboard. Final system trials confirmed full restoration of the starboard windlass/mooring winch, now operating to standard. Recommendations: Qualships advises regular inspection of hydraulic components, timely flushing, and filter replacement schedules to avoid similar faults in future. This successful operation reinforces Qualships’ commitment to delivering high-quality marine engineering support with minimal operational disruption. For more information about Qualships services, please contact info@qualships.com or visit www.qualships.com.

Read More...ROLLS ROYCE WINDLASS /WINCHES HYDRAULIC TROUBLE RECTIFICATION

Qualships Completes Critical Hydraulic Repair at Port Botany Port Botany, Australia — 17 May 2025 In a successful display of marine engineering expertise, Qualships Pty Ltd has completed the comprehensive rectification of an inoperative starboard windlass/mooring winch hydraulic system aboard a major container vessel. The intervention took place at Port Botany under instruction from Ship Owner, ensuring minimal downtime and restoring critical anchoring capabilities to the vessel. Upon boarding and conducting initial diagnostics, the Qualships engineering team identified a complete failure in the hydraulic system. Pressure readings taken after the control block and before the hydraulic motor indicated zero pressure—pinpointing a fault within the control block as the root cause. The control block, comprising three sections, was systematically dismantled and off-landed along with associated hydraulic piping. The blocks were cleaned, disassembled, and thoroughly inspected at the shore facility. A major issue was identified in the pilot assembly cartridge valve, where a broken washer and debris had caused internal flow bypass, rendering the windlass inoperative. Key remedial actions included: Renewal of all seals, O-rings, and backup rings. Replacement of all nuts and bolts. Polishing of cartridge valve and slide surfaces. Removal and rethreading of broken studs from Block C. Post-repair, the control blocks underwent bench testing and were reinstated onboard. Final system trials confirmed full restoration of the starboard windlass/mooring winch, now operating to standard. Recommendations: Qualships advises regular inspection of hydraulic components, timely flushing, and filter replacement schedules to avoid similar faults in future. This successful operation reinforces Qualships’ commitment to delivering high-quality marine engineering support with minimal operational disruption. For more information about Qualships services, please contact info@qualships.com or visit www.qualships.com.

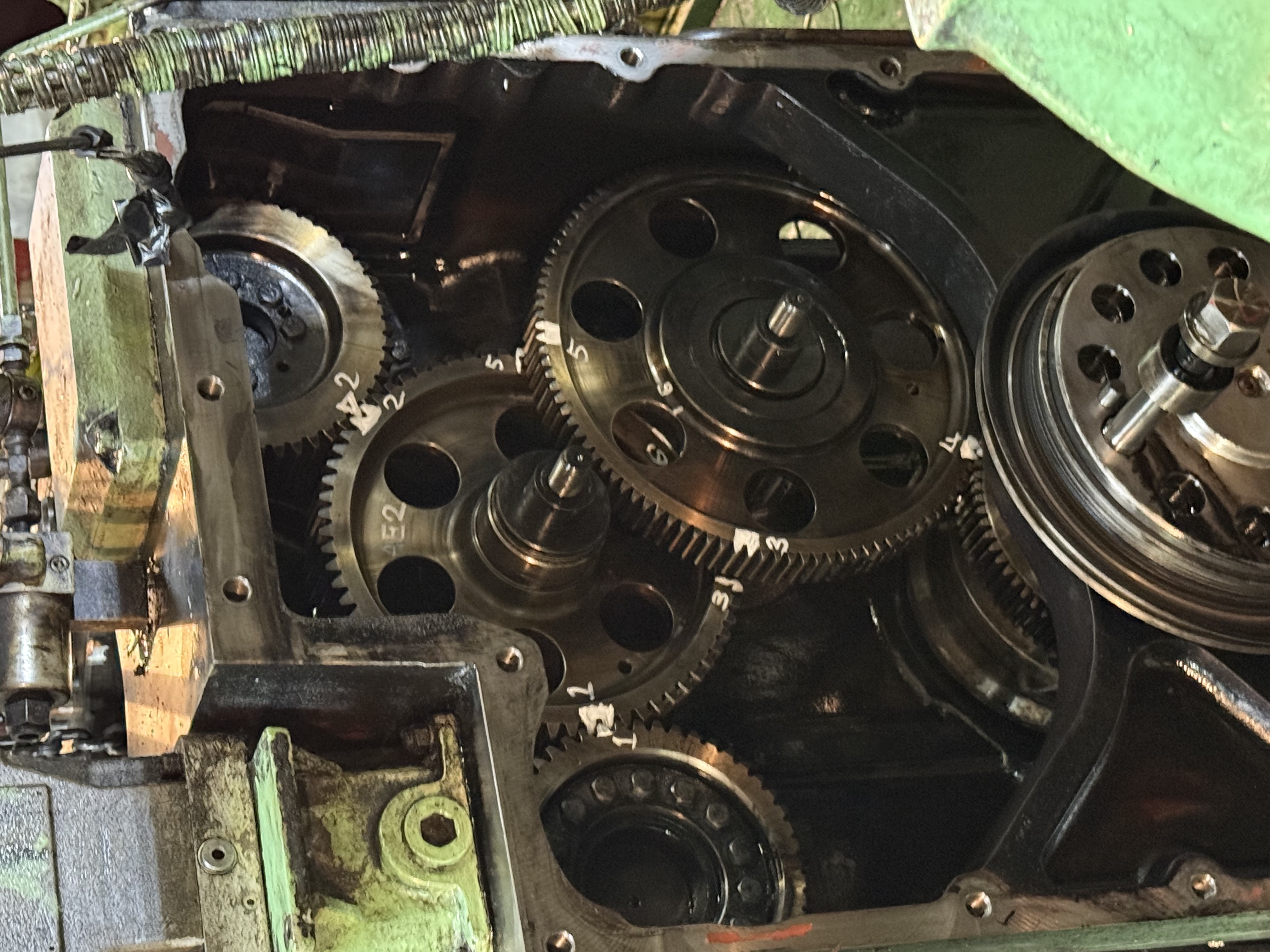

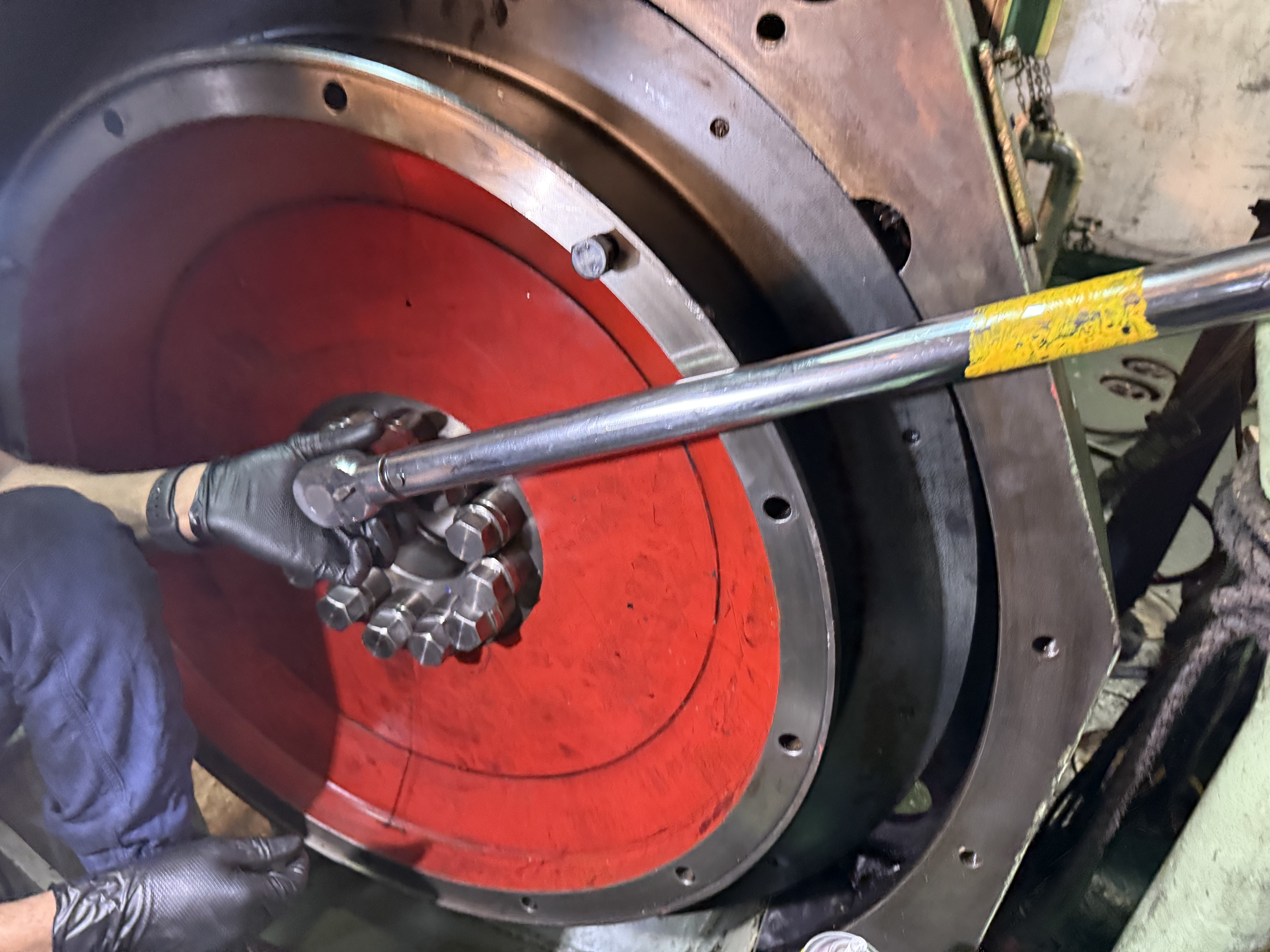

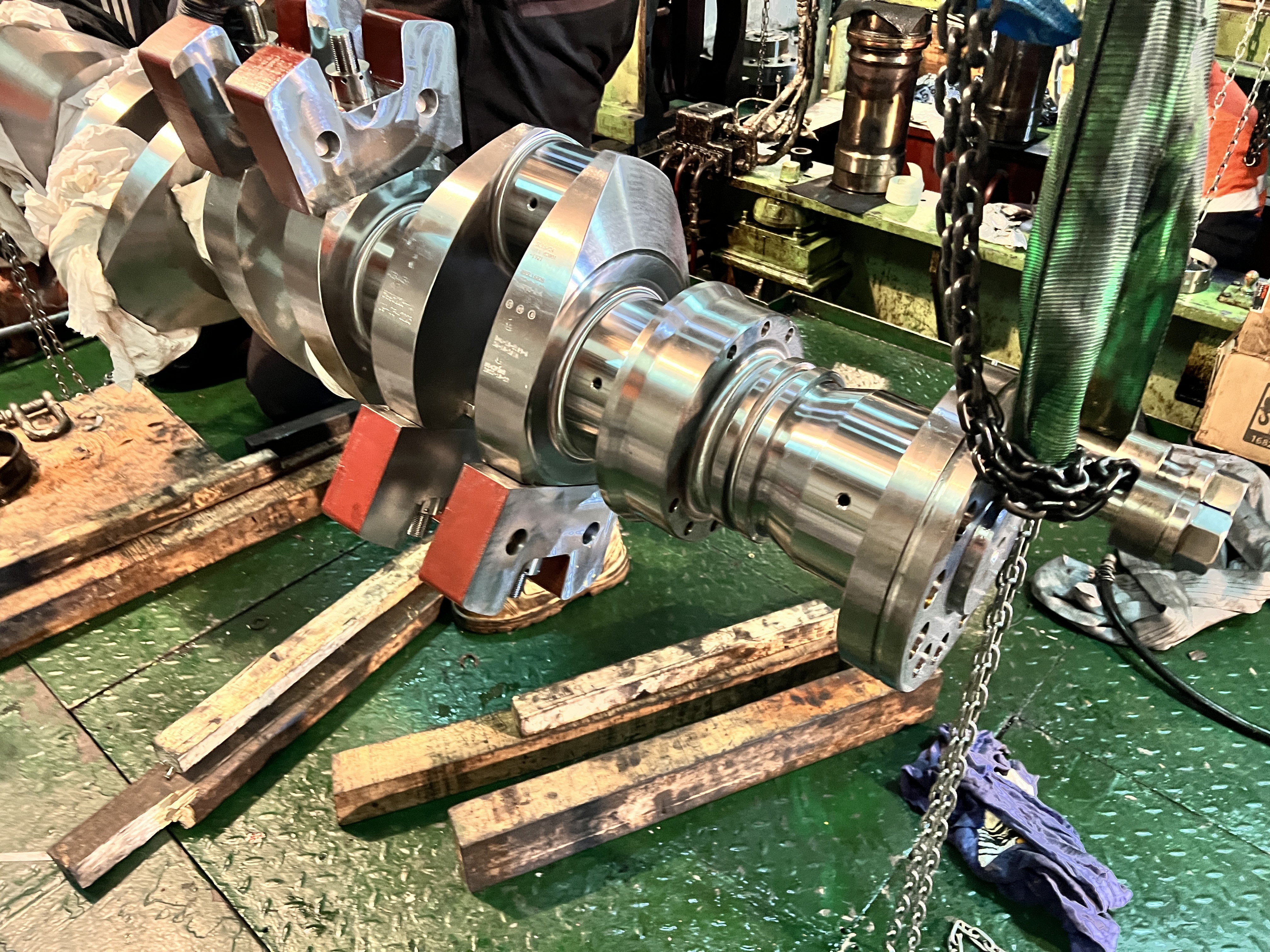

Read More...Complete Crankshaft Renewal of Three MAN 5L16/24 Generators in New Zealand

Qualships has successfully completed a full rebuild of three MAN 5L16/24 auxiliary generators onboard a vessel in New Zealand, including complete crankshaft renewal and precise reassembly. Our expert engineering team undertook the removal of the damaged crankshafts, followed by the installation and consigning of new OEM-supplied crankshafts as per MAN specifications. Each unit was rebuilt with precision, ensuring correct bearing clearances, alignment, and torquing procedures. The entire operation was executed safely, within timeline, and to the satisfaction of the attending class surveyor and vessel superintendent. Qualships is a trusted name in marine generator repairs across Australia and New Zealand, specialising in MAN engine overhauls, crankshaft renewals, and major engine rebuilds using OEM parts and experienced technicians.

Read More...Container Ships ISO Socket and Lashing eye renewal

At Qualships PTY Australia, we successfully completed a major container ISO socket and pad eye renewal project onboard a container vessel, renewing over 140 ISO sockets. Our expert team worked tirelessly through the night to meet the vessel’s tight schedule, delivering precision welding and structural integrity at every stage. We are proud to be DNV-approved for ISO socket and container lashing point renewals. This certification underlines our technical competence and commitment to the highest standards of marine structural repair and container securing systems. Our work involved: • Safe removal of wasted ISO sockets and pad eyes • Fabrication and fit-up of new ISO sockets • Class-approved welding using qualified procedures and welders • Visual and NDT inspections to ensure compliance with classification society requirements This rapid turnaround highlights our ability to support vessels at short notice with high-quality ship repair services across Australia, including NSW, QLD, VIC, and WA. If your vessel requires ISO socket renewal, pad eye welding, or container securing system upgrades, contact us at admins@qualships.com . Qualships – Trusted Name in Class-Approved Ship Repairs in Australia.

Read More...Showing 1 to 6 of 15 news posts